Who we are

We are redefining how matter is made.

NovaECAM is a deep-technology company pioneering a new era of manufacturing — where light and electrochemistry work together to build materials directly from ions.

Our proprietary Photo-Assisted Electrochemical Additive Manufacturing (PA-ECAM) platform transforms the way metals and hybrid materials are created, enabling precision that exceeds the limits of traditional 3D printing.

We don’t melt, cut, or extrude. We grow matter — atom by atom — guided by photons, electric fields, and molecular intelligence.

Our Vision

To build a manufacturing ecosystem where every functional material — from metals to dielectrics — can be digitally composed, grown, and tuned in real time.

We envision a future where hardware evolves with the same fluidity as software — adaptive, programmable, and intelligent at the atomic scale.

Our goal is simple yet transformative: to turn photons and electrons into functional matter for the industries shaping the 21st century — biomedical, aerospace, energy, computing, and beyond.

Our Technology

NovaECAM’s platform merges three scientific domains into one coherent manufacturing language:

Electrochemistry:

Metals are deposited not by heat, but by precise electrochemical reduction.

Each atom is placed exactly where needed, achieving dense, smooth, and defect-free growth.Photonics:

Light acts as a local accelerator — activating photo-mediator molecules in the electrolyte and triggering metal growth only where illuminated. This optical selectivity enables micron-level detail and multi-material complexity.Machine Intelligence:

AI-driven control learns from in-situ data — adjusting current, exposure, and chemistry layer by layer for consistent precision. The result is self-correcting, adaptive manufacturing that continuously improves.

Together, these principles allow NovaECAM to produce gradient alloys, hybrid metal-dielectric structures, and even two-phase materials — all within a single platform.

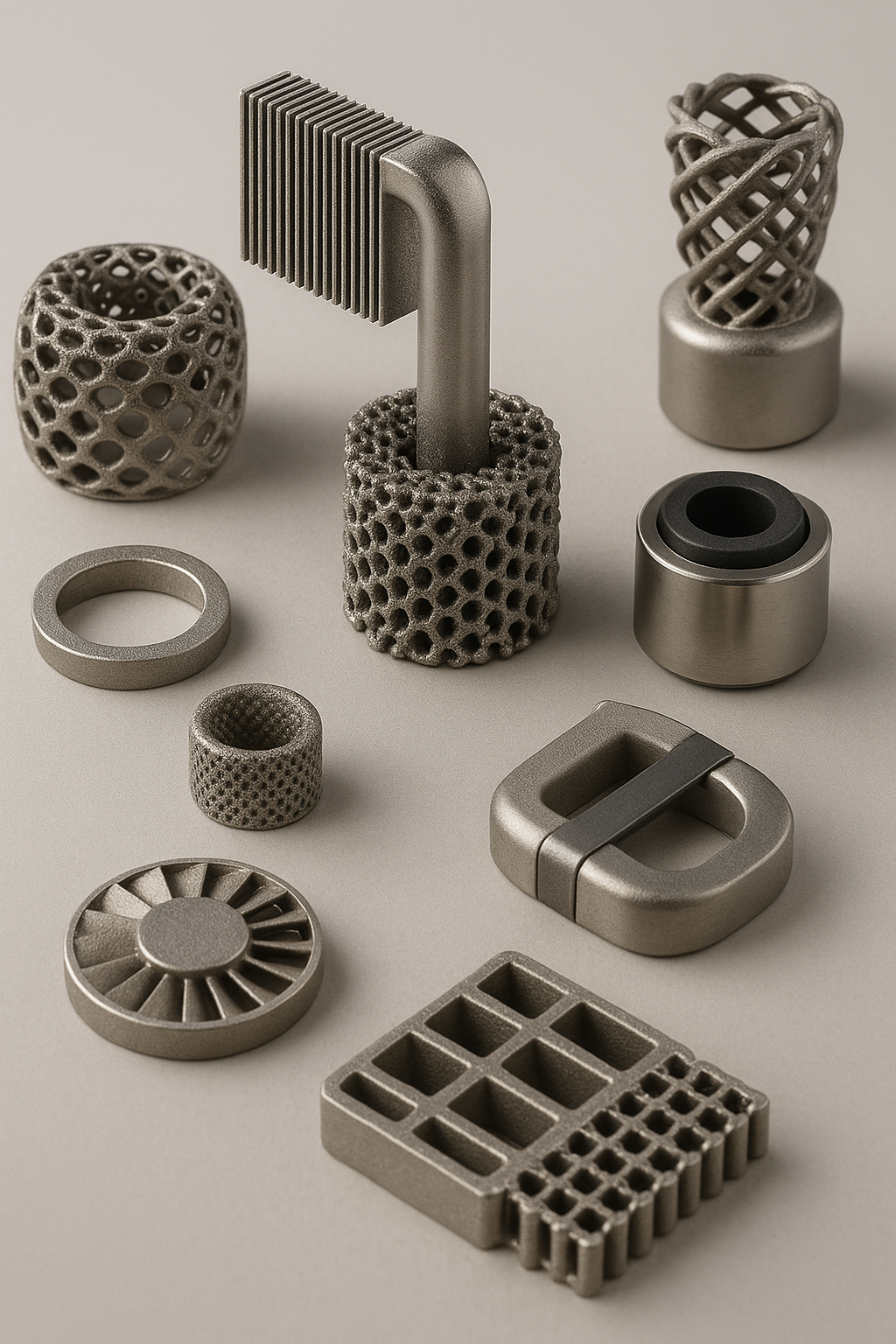

What We Create

Our technology enables a range of products and functions impossible by conventional manufacturing:

Thermal Management Systems:

Loop heat pipes (LHP), vapor-chamber cores, complex heatsink and conformal micro heat exchangers for electronics and aerospace cooling.

Electro magnetic Components:

Soft-magnetic NiFe and CoNi structures, shielding meshes, and micro-inductors.

Gradient & Multi-Material Parts:

Cu–Ni, Cu–Co, and Cu–Ag transitions with programmable composition.

Hybrid Metal–Polymer Architectures:

Integrated dielectric zones and sensor structures printed in the same process.

Functional Micro structures:

Porous lattices, catalytic surfaces, and embedded sensing networks.

Each component is made with near-zero waste, low energy consumption, and precise control over microstructure and composition.

Our Impact

By merging photonics and electrochemistry, NovaECAM eliminates the constraints of powder-based and thermal manufacturing:

No melting.

No powders.

No waste.

No high-temperature distortion.

The result is a sustainable, electrically efficient process capable of manufacturing complex, multi-functional materials at scale — opening a path toward clean, intelligent, and decentralized production.

The Team

NovaECAM unites experts in electrochemistry, photonics, advanced materials, and machine learning — driven by a shared belief that the boundary between matter and code can disappear.

Our lab combines scientific rigor with rapid prototyping, enabling discoveries to move from theoretical to physical in weeks, not years.

We collaborate with leading research institutions and industrial partners in aerospace, electronics, and energy — building the foundation for a new manufacturing paradigm.

NovaECAM — From Light to Matter.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!